Car-O-Liner is a top-notch global provider of cutting-edge collision repair solutions for automotive body shops.

For more than half a century, they’ve delivered an innovative approach, technical development and support that have created a lasting impact on customers and the auto body repair industry.

Today, innovation in collision repair technology is pivotal to achieving repair efficiency, restoring beyond pre-accident conditions, and enhancing safety and vehicle performance.

Advanced technology paves the way for reduced operating costs and high-quality service outcomes. The idea was to provide unprecedented precision in vehicle restoration and to embrace sustainability.

History of Car-O-Liner

It all started in 1973 in Gothenburg, Sweden. Car-O-Liner is a brand known to produce various equipment of mechanical measuring systems and alignment bench systems used for the restoration of damaged vehicles like cars, buses and trucks.

Today, the company has full-on coverage of versatile collision repair systems—all of which are praised for being modern, top-tier and ergonomic.

Some of the major advancements of Car-O-Tronic technology include the following:

The Car-O-Tronic measuring system is one of the most robust electronic measuring systems you can find in the market today.

Combined with Vision2 software, this ground-breaking vehicle damage assessment process featuring a sensor-equipped measuring slide and a built-in remote control offers real-time measurements to ensure accurate repairs.

Evo Universal Fixture Kit is another key technology that provides a universal solution for various vehicle repairs. This product is handy for anchoring, holding and fixturing vehicle components while under repair, accurately speeding the repair process.

These breakthroughs show the accelerating trend of optimising modern technology to secure safety, quality and efficiency in the collision repair industry.

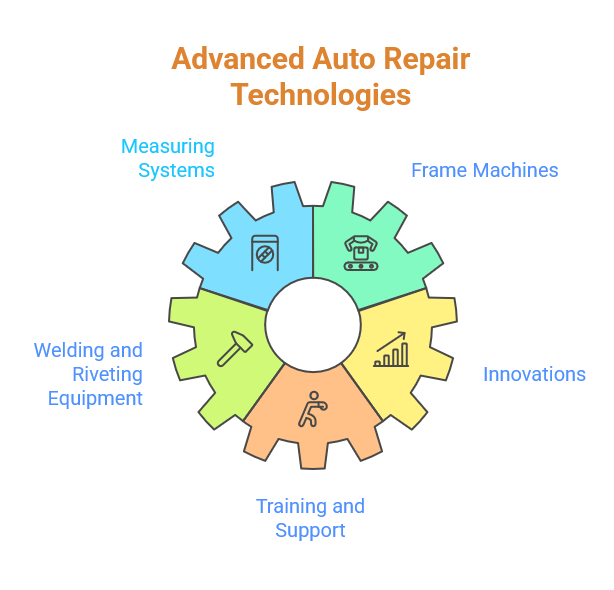

Key Technologies

Measuring Systems

Electronic and 3D measuring systems are products of advanced technology leveraged for precise evaluation of vehicle identity and structure.

These systems use sensors and advanced cameras to present a comprehensive 3-dimensional image of the vehicle, especially helpful in assessing automobiles with complex designs.

There are many advantages to utilising electronic and 3D measuring tools, including restoration of the vehicle to its original specifications and guaranteeing structural integrity and safety.

And with the risks of errors greatly reduced, you can avoid wasting materials and costly repeat repairs.

Frame Machines

Frame machines are an important piece of auto body shop equipment that is responsible for repairing the structural damage to your vehicle during a collision.

Car-O-Liner’s frame machines are specifically designed to hold different types of vehicles. They boast features that enhance stability and effectiveness during repairs, like adjustable fixtures and hydraulic pulling systems.

These elements lead to effective repairs that significantly strengthen the vehicle’s safety and performance.

Welding and Riveting Equipment

Welding builds the very foundation of your car’s makeup.

Advanced welding technologies like the CTR 9 spot welder are particularly helpful in providing fast and efficient patches in critical areas of your car. These tools ensure that your vehicle’s components are durably fastened and connected.

Riveting equipment is also an essential tool to securely join components together, mainly for modern automobiles where rivets are commonly found.

Robust welding and riveting add strength to your vehicle, encouraging structural integrity and safety.

Innovations Driving Efficiency

For decades, Car-O-Liner has introduced products to elevate repair performance in auto body shops, making them faster and more efficient.

Just take their innovative creations of Car-O-Tronic Vision X3 and their complete line of welding systems, allowing accurate and swift assessment and repair. This results in a more streamlined workflow, alleviating manual process and reducing errors.

Reports say that Car-O-Liner’s systems made collision repairs 30% faster without compromising quality, boosting performance and customer approval.

Training and Support

Car-O-Liner wants success for their customers beyond the sale. This sort of commitment prompted their creation of the Car-O-Liner Academy.

The academy is a customised solution to provide comprehensive training and coaching to support customers and maximise the performance of the Car-O-Liner equipment.

Some of the training in their five-course programs include basic electronic measuring shop training and basic resistance welder-in-shop training.

Car-O-Liner’s training and support also extend to their technicians. Their hands-on tutoring produces skilled field service technicians who are knowledgeable and practised with the latest technologies.

Ongoing education in new technologies is really pivotal to ensure efficiency in using various tools and methods. This continuous learning approach gives competence in maintaining quality standards and safety in repair jobs.

Future Trends in Auto Body Repair

The emerging technologies are going to shift the auto body repair industry. They will redefine processes and make them more efficient.

For instance, augmented reality will be leveraged to get real-time assistance while working. By overlaying digital information on screen during repair, technicians will be guided accurately on what to do and how to do it, speeding up the process.

Another one is robotic automation, poised to make a huge impact on the collision repair business. It was projected that in the next 3 to 6 years, 75% of the roles within collision repair can be greatly enhanced by robotics.

Sustainability and Eco-Friendly Practises

As the collision repair industry seeks sustainable ways to improve their business and safeguard the environment, eco-friendly practises are being adopted.

Low or no-VOC options are utilised as a more sustainable choice to promote a healthier environment.

Recycling of materials is another collision repair practise to reduce waste and conserve resources. Energy-efficient repair equipment, like solar-powered lights, is also being developed to reduce the usage of energy and environmental impact.

The consistent emphasis on cutting carbon footprints is pivotal to realising environmental goals and expectations in the collision repair industry.

Conclusion

Car-O-Liner has created leading-edge, versatile solutions in the auto body repair industry. Through their many innovations, including a universal precision milled bench, a wireless electronic measuring system, inverter resistance spot welders, and so much more, they have advocated some of the best collision repair tools.

Car-O-Liner technology has empowered not just their technicians but their valued customers as well.

Embracing innovation is crucial for the future growth of the auto body repair industry. Their adaptation will help collision repair businesses maximised productivity, prompting an efficient and sustainable future.